Education

Drexel University – Philadelphia, PA

Master of Science in Mechanical Engineering, June 2019

Bachelor of Science in Mechanical Engineering, June 2018

Danmarks Tekniske Universitet (DTU) – Lyngby, Denmark

Study Abroad, August – December 2015

Technological Skills & Languages

Mechanical Design: PTC Creo Parametric (Pro-E), AutoCAD, SolidWorks

Simulations: COMSOL Multiphysics (FEA), ANSYS, Autodesk Moldflow, FEniCS Package

Fabrication Tools: CNC, Mills, Lathe, Injection Molding, Laser cutter, 3D Printers (SLA, FDM), Soldering, Hand Tools

Programming and System Modelling: MATLAB, VBA, Python, Simulink, LabView

Electronics: Arduino, Raspberry Pi, TIVA Launchpad

Project Management & Other Skills: MIE Trak Pro (ERP/MRP), BioLogic, Linux (Ubuntu 14), Microsoft Office (MS Word, Access, Excel, Outlook), LaTex

Languages: Tamil (Bilingual), Hindi (Intermediate), German (Intermediate), Japanese (Elementary)

Work Experience

Mechanical Engineer – Strongarm Designs, PA

March 2021 – Present

- Actively collaborated with sales leads and customers to design customized operator interface solutions (OIT) for clients in industries ranging from Pharmaceuticals to Petrochemicals using Solidworks

- Developed products by equipping design principles for materials such as aluminum, stainless steel, and carbon steel to fabricate components using casting (graphite and sand casting), laser cutting, forming and welding sheet metals, and machining

- Actively collaborated with brake operators, welders, machinists, assemblers, and other production personnel to troubleshoot problems (ECR, ECO, NCMR) and lead continuous process improvement projects as part of the company-wide aggressive push to facilitate lean systems and to ultimately increase customer satisfaction

- Lead and executed Corrective and Preventive Action (CAPA) remedial projects for key clients, including destructive and non-destructive testing complete with investigative reports

- Identifying and investigating NCs (Non-conformance) in all stages of production to improve lead time and increase the quality of the end-product

- Anticipated and proactively solved design and fabrication problems in existing products to decrease lead time, reduce quality concerns, and improve final product quality; reduced throughput time for certain products from 4+ hours to less than 2 hours

- Developed and implemented new design and fabrication strategies to increase workflow in the shop by addressing key bottle-neck areas

- Developed product breakdown complete with exploded assemblies and improved assembly set-up to be apt for high-volume production

- Collaborated with purchasing managers to build sub-assemblies in the enterprise resource planning (ERP) software for high-volume production, and to procure high-volume production components as well as project-specific components

R&D Mechanical Engineer – Load Control Technologies, PA

July 2019 – March 2021

Primarily used Solidworks for design and the machine shop and 3D Printing to RP for feasibility

- Designed and integrated a non-magnetic i-bolt investigation system within 30 days as part of the production qualification process to optimize measurements at varying temperatures and reduce set-up time by 90%, to just 1 minute

- Developed the internal system design and packaging for an optomechanical system in collaboration with the electrical engineer to detect the ultrasonic transducer on bolts as part of the next generation product development to reduce product size by 50%

- Designed the packaging for a micro-scale wireless temperature sensor to optimize the ultrasonic wavelength used for load measurements and to debug any issues with the product design using root cause analysis (RCA)

- Lead feasibility studies for next-generation products with functional models using 3D Printing (Stratasys Dimensions, Lulzbot Mini, FormLabs 2), Machining and Injection Molding

- Researched and liaised with different vendors and OEMs to reduce manufacturing time

- Designed and integrated custom tooling with i-bolt technology and packaging with LoadMaster LM-3600 in equipments such as the torque multiplier and pneumatic impact wrench per customer operation requirements

- Developed equipment and actively collaborated with production personnel for continuous process improvement and lead time reduction

Project Management Co-op – PECO, PA

March – September 2016

- Crafted an automated ‘track and respond’ tool to manage on over 250 solar-grid approval requests, and directed project workflow using Alternative Energy Portfolio Standards (AEPS)

- Liaised between customers and PECO engineers at Philadelphia and Berwyn to fulfill more than 50 regional projects

- Trained two co-ops to take over the job responsibilities

March to August – 2015

- Reverse engineered the EM wave applicator MA120, an FDA compliant medical device that is used in the hyperthermia treatment of cancer and modeled it in Creo Parametric

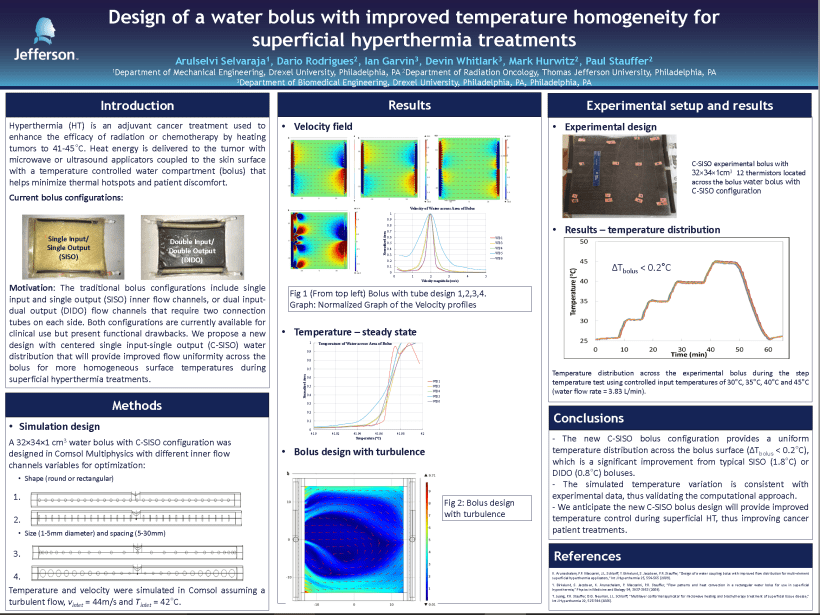

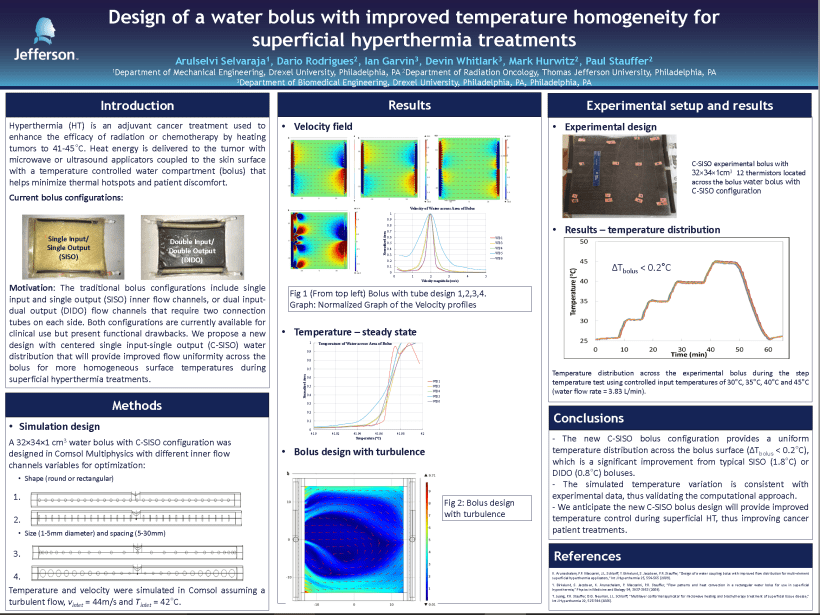

- Designed and investigated the efficacy of different water bolus designs on a heterogeneous tissue model using FEA in COMSOL with CFD, Heat Transfer, and EMW Modules to improve patient’s healthcare quality

- Developed an automated investigation system in LabVIEW and tested the heat distribution under transient and steady-state conditions using 16 thermocouples

- Drafted documentation for replicating bolus design, and shared the research poster at the 2016 NCRC Research Conference in Harvard University

Teaching Assistant & Peer Mentor – Drexel University, PA

2014 – 2019

- Taught Dynamics to a class of 120 mechanical engineering students, and developed lesson plans and exams in collaboration with the professor

- Collaborated with the Lindy Center team and various professors within Drexel to teach and mentor 200+ freshman engineering classes to develop experiments such as basket robots and airfoil testing for demonstration within the Philadelphia community; includes coordinated presence during the Franklin Institute Science Festival in Philadelphia

- Mentored various classes of 40 incoming freshmen with the Rube-Goldberg experiment, which involved working with renewable sources of energy, energy transfer methods, and 3D printing; includes at least 48 unique experimental setups

- Mentored senior design student groups in projects, and maintained the logistics for the Senior Design for the graduating class of 240+ students

Research Assistant – Drexel University, PA

2015 – 2016

- Constructed open tunnel oxides of transition metals using a variable combination of a thermoplastic fluoropolymer and carbon black

- Devised three-electrode cells with fabricated material to investigate electrochemical capabilities using BioLogic VMP3

- Replicated paper contents to assess the ability of the test material against different concentrations of acidic and basic electrolytes

- Liaised with a colleague and supervisor to evaluate the electrical properties of the test material

June to September – 2014

- Worked on understanding the theory behind the mechanics of materials at a nanoscale level

- Investigated the characteristics of Aluminum atoms subjected to nanoindentation, for different indenter orientations using Large-Scale Atomic/Molecular Massively Parallel Simulator (LAMMPS), a Molecular Dynamics Program.

- Analyzed the raw data acquired from virtual stimulation using OVITO and Matlab

- Composed a poster and presented it during the STAR Summer Showcase and Drexel Research Day

Leadership and Community Experiences

- Outreach Director, ASME Philadelphia, 2019 – Present

- Community Volunteer, Lindy Center, Drexel University, 2014 – 2019

- Peer Mentor, Drexel University, 2014 – 2017

- Events Coordinator, Drexel Design Makers, and Thinkers (DLab), 2016-2017

- Volunteer, Lindy Center, 2014 – 2016

- Events Coordinator, Tau Beta Pi, 2015

- Outreach Chair, Society of Women Engineers, 2014

Honors and awards

- A. J. Drexel Scholarship, Drexel University, Fall 2013 – Spring 2018

- Dean’s list, Drexel University, Fall 2013 – Winter 2015

- Paul Peck Scholar, Drexel University, Fall 2014 – Spring 2016

Research Conferences

- National Collegiate Research Conference, Harvard University, MA, 2016

- Naval Academy Science and Engineering Conference, Annapolis, MD, 2014 (Robotics concentration)

Project Experience

Hobby Projects (CAD & Control Systems) – Ongoing

Please note that the below-mentioned projects are hobby projects.

- Designed autonomous CAD models inspired by Legos and drones; verified joint integrity and kinematics through stress and motion analysis respectively

- Modeled an aerial vehicle with a viable aerodynamic airfoil based on CyPhy Works LVL 1 drone in Creo (surface modeling); analyzed the kinematics of the model using servomotors

- Applied surface modeling to model parts comprising sculptured surfaces including an electronic mouse, a shaver, and a helmet based on images

- Determined the inverse kinematics and dynamics using Lagrangian Dynamics and DH parameters, and implemented the path planning methodology for the virtual models using MATLAB/Simulink

- Investigated the effects of different controllers such as PI, PID, LEAD and Observer-based feedback controls

- Developed dynamic models and numerical solutions for different robots using root-finding methodologies such as Newton Raphson, Secant, and Bisection in Python and MATLAB

Analyst/Programmer

August to December – 2015

- Calculated the Cartesian and Joint-Space trajectories along the tool path of the robot, with five degrees of freedom using real-time variables

- Determined the inertia tensor, and the linearized, decoupled dynamic model based upon DH parameters featured in related literature

- Modeled PI, PID and LEAD controllers on Simulink; assessed the impact of controllers on Alto Robot

Lead Designer/Programmer

January to June – 2014

- Designed a robotic arm with a multi-use end effector and four degrees of freedom using a Solid Modeling and Surface Modeling software (Pro-E/Creo)

- Effectively mimicked the arm movement using Arduino and tilt sensors; optimized the data via MATLAB

- Assembled and delivered a formal report and presentation to detail the significance and limitations of the robotic arm